Predictive Maintenance

MicroDAQ: Shift from Reactive Repairs to Predictive Maintenance with Powerful Data Loggers

MicroDAQ empowers you to embrace a proactive approach to maintenance with our feature-rich data loggers. Move beyond reactive repairs and costly downtime by implementing a predictive maintenance strategy. Our data loggers capture a wide range of parameters critical to equipment health, including vibration, pressure, and RPM. By continuously monitoring these vital signs of your machinery, MicroDAQ data loggers identify subtle changes that may indicate potential problems before they escalate into major failures. With customizable alerts and user-friendly software, you can schedule preventive maintenance based on real-time data, avoiding unexpected downtime and optimizing equipment lifespan. MicroDAQ data loggers empower you to maximize production efficiency, minimize repair costs, and gain a deeper understanding of your machinery's health for informed decision-making.

What Can Predictive Maintenance Do For You?

- Identify Machine Problems Before They Become Serious

- Reduce Unplanned Equipment Downtime and Critical Failures

- Provide Immediate Machine Condition Statuses

- Reduce Scheduled Time Based Maintenance

- Improve Maintenance Troubleshooting

- Confirm Quality of Repairs

- Improve Product Quality

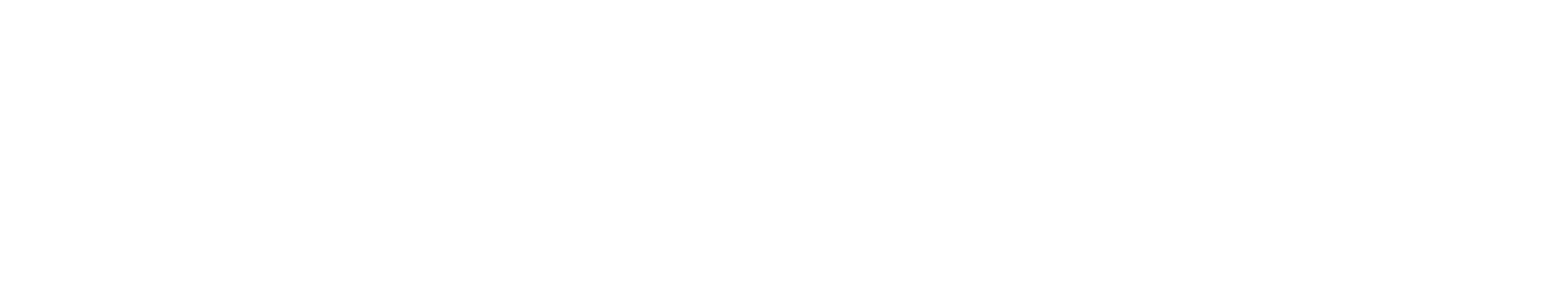

A comprehensive predictive maintenance program consists of vibration monitoring, infrared thermography and visual inspection. MicroDAQ.com offers all the equipment you need to implement and maintain a successful predictive maintenance program. Analysis of these areas can reduce costly down time of machinery by scheduling maintenance only when it is needed. With the right tools you can predict when the machinery will require maintenance.

Vibration Analysis – Vibration meters and loggers can identify a problem before the equipment fails by detecting misalignment or an imbalance of rotating machines. Defective bearings or loose parts are a few examples of problems that can cause an increase in vibration.

Infrared Thermography – IR Thermometers are used to safely get noncontact temperature readings of equipment to identify if the equipment is overheating

Visual Inspections – Stroboscopes and Tachometers are both helpful in this area. Stroboscopes allow slow motion or stop action visual inspection of rotating, linear or reciprocating objects. With the stroboscope you can visually inspect the parts of the machine for signs of wear or cracks without having to stop it. Tachometers are used to get RPM measurements. MicroDAQ.com offers both contact and noncontact tachometers.

-

R7000SD-KIT

R7000SD-KIT- Acceleration & Vibration Measurement with Frequency Range Meeting ISO 2954 Standards (10-200r/s)

- Recorded Data Logs to SD Card with Easy Analysis Using Microsoft® Excel®

- Backlight LCD Display Shows Current, Min and Max Readings and Battery Status

- 1 Second to 1 Hour User-Selectable Sampling Rate

- No Software Required, Data Logs to SD Card (Sold Separately)

Kit includes Vibration Sensor with 1.2 Meter (3.93 ft) Cable, 16 GB SD Card, AC Power Adapter and Hard Carrying Case

-

6241-010

6241-010- Designed for Simple Stroboscopic Stop Motion Inspection and RPM Measurement

- Extremely High Flash Rate Up to 999,999 FPM

- 12 LED Stroboscope Light Source - Bright but Cool

- Replaceable and Rechargeable Li-ion Battery-Powered or AC-Powered

- 6-Digit Numeric and 5-Digit Alphanumeric LCD Display

- Tachometer Optional Integral Laser Module Can be Added

Includes User Manual and Product Registration Card

-

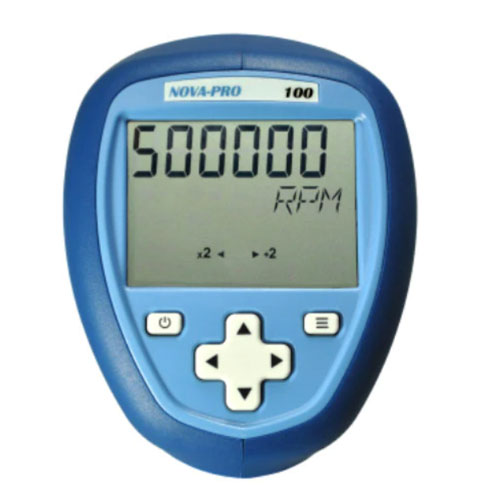

6125-010

6125-010- 32 Function Tachometer/Ratemeter, Totalizer/Counter and Timer (Stopwatch)

- Accurate and Continuous Operation with "Locked-On" Mode and Tripod (Sold Separately) Mounted

- Optical Range up to 200,000 RPM and Contact Range up to 20,000 RPM

- External Inputs for Remote Contact Assembly (RCA) and Remote Sensors (Optional)

- LCD Display Shows Last, Maximum and Minimum Readings and Operating Indicators

Includes 12" Reflective Tape, (2) AA Batteries and NIST Certificate of Calibration.

-

Pocket LED Stroboscope$520.006235-010

Pocket LED Stroboscope$520.006235-010- 0 to 300,000 FPM (Flashes per Minute) Flash Range with +/-0.005% Accuaracy

- 3 Separate Modes of Operation: Internal, External and Charging

- Adjust Flash Pulse Width Using Degree of Rotation or Pulse Duration Adjustments

- Input and Output Jacks for External Triggering and Synchronization of Multiple Stroboscopes

- Digital LCD Display with 4-Button Keypad for Field Control and Operation

Includes Universal 115/230 Volts AC Recharger with Universal Wall Plugs, NIST Calibration Certificate and User Manual

-

6204-012

6204-012- 30 to 20,000 FPM (Flashes per Minute) Flash Range with +/-0.002% Accuracy

- 3 Separate Modes of Operation: Internal, External and Charging

- Adjust Flash Pulse Width Using Degree of Rotation or Pulse Duration Adjustments

- Digital LCD Display with 6-Button Keypad for Field Control and Operation

- Programmable Memory Stores and Recall up to 6 User Selectable Values

Includes Universal 115/230 Volts AC Recharger with International Wall Plugs, NIST Calibration Certificate and User Manual

-

R7000SD

R7000SD- Acceleration & Vibration Measurement with Frequency Range Meeting ISO 2954 Standards (10-200r/s)

- Recorded Data Logs to SD Card with Easy Analysis Using Microsoft® Excel®

- Backlight LCD Display Shows Current, Min and Max Readings and Battery Status

- 1 Second to 1 Hour User-Selectable Sampling Rate

- No Software Required, Data Logs to SD Card (Sold Separately)

- Battery-Powered with Optional AC/DC Powered Adapter (#RSD-ADP-NA) Available

Includes Vibration Sensor with 1.2 Meter (3.93 ft) Cable, and Hard Carrying Case

-

R8500

R8500- High Resolution 2.5" Color LCD Monitor

- 9mm Waterproof (IP67) Camera Head

- 1 Meter (39") Gooseneck Cable

- (4) High Visibility LED Lights for Darken Environments

- Low Battery Indicator and Auto Shut Off

Includes Magnet, Hook and Mirror Attachments, (4) AA Batteries, USB Cable and Hard Carrying Case